fabric bursting strength testing|bursting strength of fabric : wholesaler ASTM D3786/D3786M-2018 “Test Methods for Textile Bursting Strength Diaphragm Method”. ISO 13938-1:2019 Textiles. Expansion properties of fabrics. Part 1: Bursting strength and expansion. Hydraulic method. ISO 13938-2:2019 “Textiles. Expansion properties of fabrics. Part 2: Determination of expansion strength and expansion dilatancy.

WEBThe odds of winning on a physical slot machine is around 1 in 49,836,032. The average return-to-player (RTP) rate is usually 92-97%, with online slots having better payout percentages than casino machines. Online casinos like ours have a paytable in every game, where you can read about payout rates, prizes, and bonus features for that slot.

{plog:ftitle_list}

Resultado da Veja o perfil de Kaline MariaKaline Maria no LinkedIn, a maior comunidade profissional do mundo. Kaline tem 1 vaga no perfil. Veja o perfil completo no LinkedIn e descubra as conexões de KalineKaline .

What is the Fabric Bursting Strength Test? The burst strength of the fabric is typically determined through a standardized test method called the “bursting strength test.” During this test, a defined pressure is applied to a fabric .ASTM D3786 – Standard Test Method for Bursting Strength of Textile Fabrics – Diaphragm Bursting Strength Tester Method: This ASTM standard outlines the procedure for determining the bursting strength of textile fabrics using a .In some standards they advise to use a smaller or bigger dome. Some standards make provision of a sample not bursting. For example in ASTM D3786, it states: If the fabric does not burst, the report should state the maximum bursting .Zhang Zhuo, in accordance with GB/T 19976-2005 “Textiles-Determination of bursting strength-Steel ball method”, the operation method of the steel ball method, using INSTRON 4465 universal material testing machine (CRE), the .

Burst strength testing. Burst testing measures the strength of fabrics and materials, by providing pressure (force) on the material from all directions equally at the same time, to measure the conditions that will cause it to rupture. When a fabric 'fails' due to bursting, it means that the fabric has a low breaking extension.ASTM D3786/D3786M-2018 “Test Methods for Textile Bursting Strength Diaphragm Method”. ISO 13938-1:2019 Textiles. Expansion properties of fabrics. Part 1: Bursting strength and expansion. Hydraulic method. ISO 13938-2:2019 “Textiles. Expansion properties of fabrics. Part 2: Determination of expansion strength and expansion dilatancy.

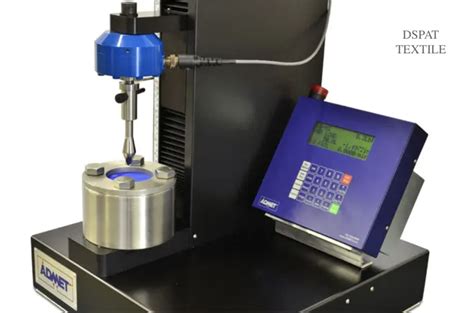

Its main features are fast response speed, high control accuracy, low noise, and simple operation. It is suitable for various textile stretching, tearing, bursting, fixed elongation, fixed load, suture slip, stripping, and other mechanical properties testing or UTM testing. Electronic Textile Strength Analysis machine testing methods and principles “Mullen burst” is a type of test that assesses the strength of a fabric by using a bursting method, or determining how much force is required to rupture the fabric as it is distended. The test method used is ASTM D3786: “Standard Test Method for Bursting Strength of Textile Fabrics—Diaphragm Bursting Strength Tester Method,” and it is .

Contents hide. 1 1 Domestic and international standards for the determination of bursting strength of textiles. 2 2 Comparison of domestic and international textile bursting strength testing methods 5.2 In cases where test results obtained using the procedures in Test Method D3786 have not been correlated with actual performance, Test Method D3786 is considered satisfactory for acceptance testing of commercial shipments of textile fabrics for bursting strength since the method has been used extensively in the trade for acceptance testing. In . 1.1 This test method describes the measurement for bursting strength of woven and knitted textiles taken from rolls of fabric or fabric taken from garments. Note 1: For the measurement of bursting strength with a hydraulic or pneumatic machine, refer to .

This machine is used to test bursting strength in the fabric testing laboratory. It has a hydraulic system for pressure, which is either achieved by oil or glycerin. The fluid is 96% chemically pure glycerin. The hydraulic system should be free of any external vibrations. Clamps are also used to uniformly secure test samples. Fabric Tensile Strength Test Methods. Grab Strength Test: At first we take specimen 4”x6”.; Then the specimen is marked by a pencil at 1.5“from the edge of the specimen to assist in clamping it so that the same set of threads are clamped in both jaws.; The two jaws are fixed on both side of the specimen from 1” edge.D 1776 Practice for Conditioning Textiles for Testing2 D 3786 Test Method for Hydraulic Bursting Strength of Textile Fabrics Hydraulic Diaphragm Bursting Strength Tester Method3 3. Terminology 3.1 Definitions: 3.1.1 bursting strength, n—the distending force, which is applied at right angles to the plane of the fabric, under specific

IS 1966 (Part 1 ): 2009 ISO 13938-1 : 1999 3.3 bursting strength (strength at burst): Pressure obtained by subtracting the diaphragm pressure from the mean bursting pressure. 3.4 diaphragm pressure: Pressure applied to the diaphragm, with no test specimen present, to distend it to the mean bursting distension of the test specimen. Result: The overall mean tear force across weft, in newton (N) or centinewton (cN). 2. Wing Rip Tear Test: The Wing rip tear test overcomes some problems which are found with the single rip test as it is capable of testing .

Test Procedure of Textile Bursting Strength Test. 11.1 Test all wetted test samples under the standard conditions described in 9.1. 11.2 Manual Hydraulic Tester: 11.2.1 Insert the sample under the tripod so that the sample .

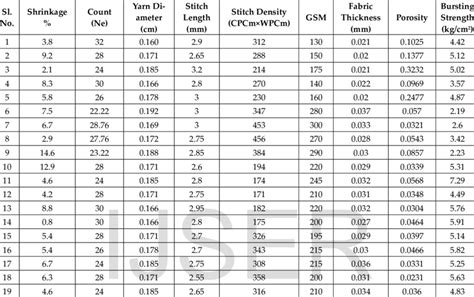

conflicting results and used different test for bursting strength. Additionally, none of the previous work used commercially available fabrics to examine bursting strength of fabrics along with extension that could impact the comfort level for the wearer. The test used for the reported study is fairly new and has not yet been tested extensively.Pneumatic Bursting Strength Tester for bursting strength and fatigue tests. Suitable for knitted and medical textiles, nonwovens, paper and plastics. . Explore our range of innovative and market leading textiles testing instruments. Speciality. Targeted and precision testing instruments for textiles used in a range of physical and demanding . Fabric Bursting Strength Test by Diaphragm & Ball Method; Different Types of Fabric Tearing Strength Test Method; Mazharul Islam Kiron. Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. He is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.

material bursting strength test

In conclusion, choosing the right fabric bursting strength tester requires careful consideration of factors such as the type of fabric being tested, the testing standards and requirements, the .

When it comes to textiles, tear strength is a crucial factor in determining the durability and quality of fabric. It refers to the resistance of a fabric to tearing under stress or force. Properly measuring tear strength is crucial for textile manufacturers, designers, and quality control professionals. It ensures that their products meet industry standards.This document describes a hydraulic method for the determination of bursting strength and bursting distension of textile fabrics. In this document, a hydraulic pressure is applied using a constant rate of pumping device. . nonwoven and laminated fabrics. It can be suitable for fabrics produced by other techniques. The test is suitable for . 5.2 Test results obtained using the procedures in Test Method D3787 have not been correlated with actual performance. Test Method D3787 is considered satisfactory for acceptance testing of commercial shipments of textiles fabrics for bursting strength since the method has been used extensively in the trade for acceptance testing. In cases of .

The pressure is increased smoothly until the test specimen bursts. The bursting strength and bursting distension are determined. 5 Sampling . highly expansive fabrics (e.g. fabric test specimens whose height at burst is greater than half of the test specimen diameter). All test specimen clamping ring inner diameters shall be accurate to ± 0 .

For more information on textile testing methods/standards or textile testing machines, contact us: What’s App: +86 180 2511 4082 Tel: +86 769 2329 4842 Fax: +86 769 2329 4860 Email:[email protected] .

knitted fabric burst strength

WEBAcompanhe as últimas notícias sobre o Esporte Clube Bahia, o time de futebol de Salvador. Veja os resultados, as entrevistas, as fotos e os vídeos do esquadrão baiano.

fabric bursting strength testing|bursting strength of fabric